Description

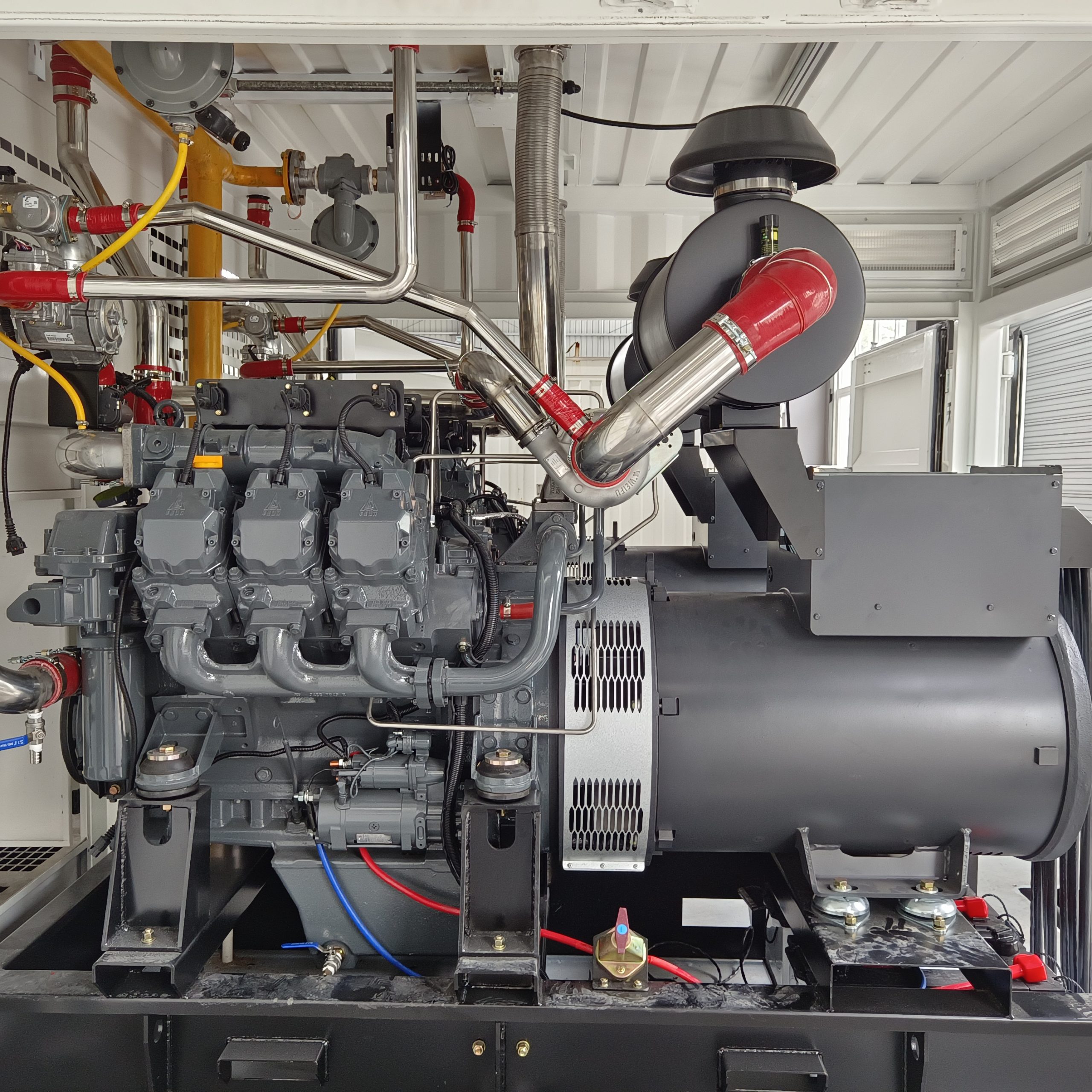

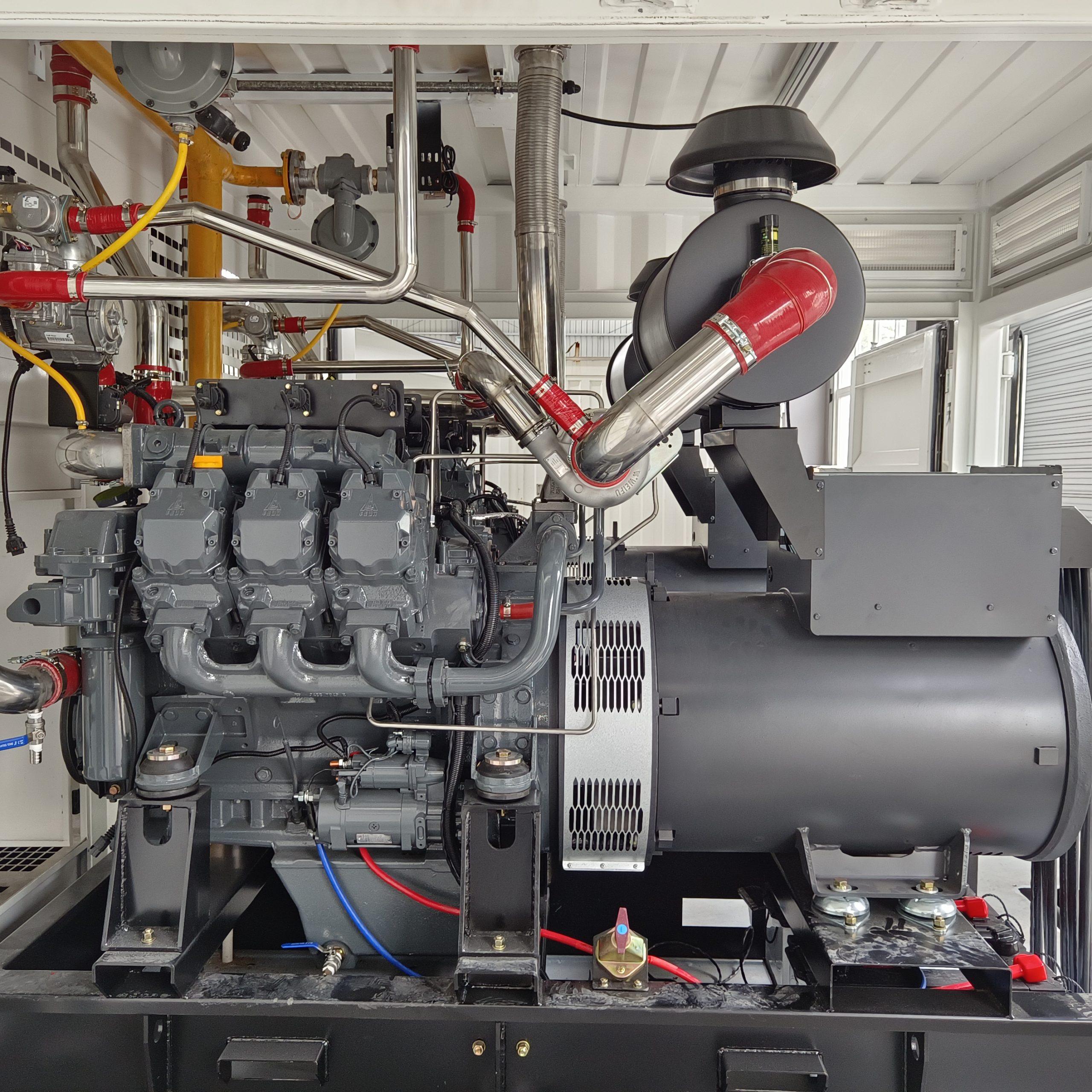

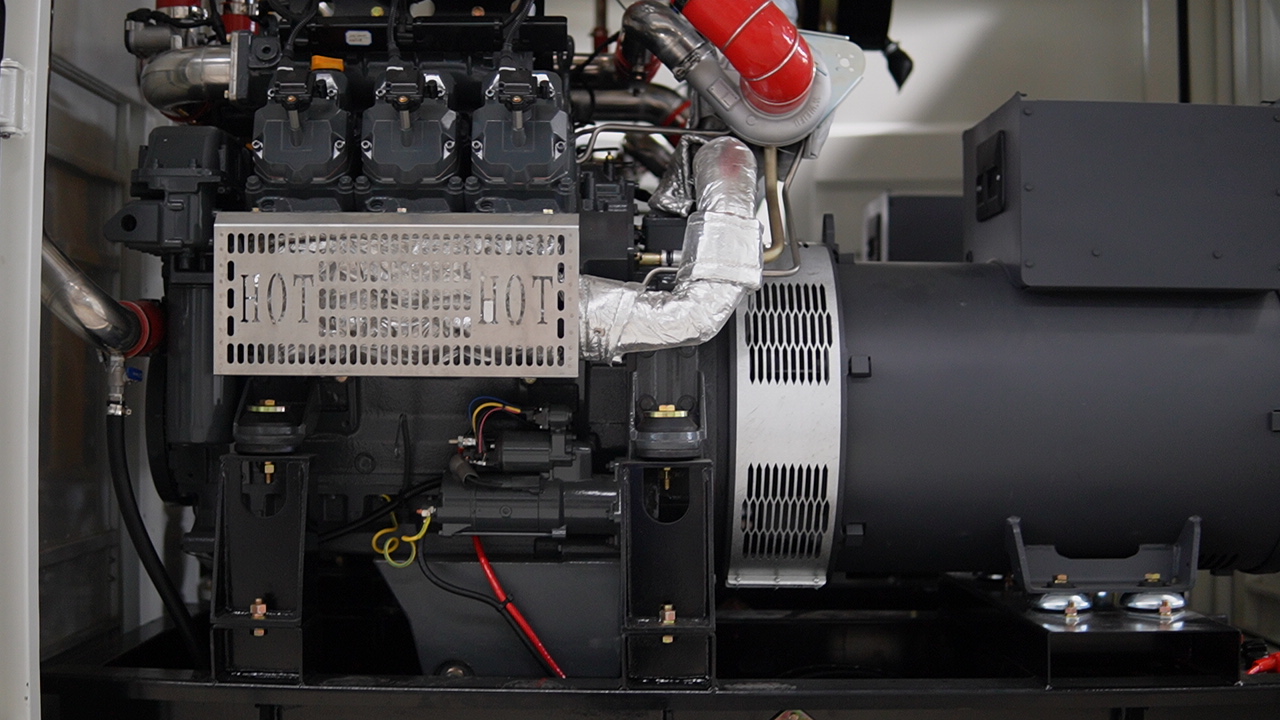

1200kW (320KW*4) 50HZ Natural Gas Generator set

Main configuration and features

Model : ED1200NGB-6/4(HC6V132) ED1200NGS-6/4(HC6V132)

- High-efficiency gas engines;

- alternating current synchronous generators;

- Safety gas valve manifold, optional gas leakage protection device;

- Suitable for cooling systems with ambient temperatures up to 50°C;

- Rigorous factory testing of all generator sets;

- Muffler: Industrial muffler with noise reduction capacity of 12-20dB (A);

- Advanced engine control system: ECI control system includes: ignition system, speed control system, protection system,

- air-fuel ratio control system and cylinder temperature;

- Equipped with cooler and temperature control system to ensure the normal operation of the unit at 50°C ambient temperature;

- Independent electrical control cabinet, can be configured with remote monitoring system;

- Multi-function control system, easy to operate;

- Data communication interface integrated in the control system to meet the data acquisition;

- Monitor battery voltage and charge automatically;

| Fuel type | Natural Gas |

| Device model | ED1200NGB-6/4 (Rainproof Box Unit) / ED1200NGS-6/4 (Silent Box Unit) |

| Equipment composition | Power system + heat dissipation system + unit control system + steel structure base + rainproof box |

| The generator set meets the standard | ISO3046,ISO8528,GB2820, CE |

- Rated data

| Load |

50% |

75% |

100% |

|

| Rated electrical power output |

kW |

600 |

900 |

1200 |

| Continuous operating power |

kW |

900 |

||

| Fuel heat |

kW |

1707 |

2509 |

3322 |

- Power generation efficiency

|

Load |

50% |

75% |

100% |

|

| Power generation efficiency |

% |

35.1 |

35.8 |

36.1 |

| (A)/ 600V / F=0.8 Rated current (A) / 600V / F = 0.8 |

721 |

1082 |

1443 |

- Special Statement:

This information is only part of the case indicators, new products will have more complete information according to the

project, please get the complete data when ordering.

- Mains power operating data

| Connection type |

Star, 3P4h |

|

|

Frequency |

Hz |

50 |

| Power factor |

0.8 |

|

|

Class (H) KVA power rating |

KVA |

1500 |

|

Generator voltage |

V |

600 |

| Current rating |

A |

1443 |

| Accumulator |

Ah |

4-160×2 |

| Startup mode |

DC24V electric start |

|

| Unit operation type |

One-key automatic start and stop |

- Genset performance data and manufacturing technology

| Allowable overload run time 1.1 times (hours) |

1 |

Signal Interference Factor (TIF) |

≤50 |

|

| Voltage setting range |

≥±5% |

Signal Harmonic Coefficient (THF) |

≤2%,as per BS4999 |

|

| Steady-state voltage deviation |

≤±2% |

Transient Frequency Regulation (60%) |

-12%~10% |

|

| Transient voltage deviation (60%) |

-10%~15% |

Frequency Recovery Time (s) |

≤1 |

|

| Voltage Recovery Time (s) |

≤1.5 |

Steady-state frequency band |

0.5% |

|

| Voltage fluctuations |

1% |

Recovery response time(s) |

0.5 |

|

| Steady-state frequency regulation |

±0.5% |

Sinusoidal distortion rate of the line voltage waveform |

≤ 5% |

|

Machinery manufacturing process

- Special welded chassis, built-in shock absorbing pad, overall hoisting

- Advanced paint layer, wear-resistant and scratch-resistant, bright and long-lasting

- Installation manual, operation and maintenance manual, circuit diagram are provided with it

The products comply with standards and relevant certifications

- ISO3046,ISO8528,GB2820

- BS5000PT99, AS1359, CE certification

IEC34ISO9001: 2016 Quality Management System Certification

- Emissions data

| Exhaust flow (wet) |

6141 kg/h |

|

|

Exhaust Flow (Dry) |

5075 Nm³/h |

|

| Exhaust flue gas temperature |

510 ℃ |

|

| The maximum allowable exhaust back pressure at the front end |

4Kpa |

|

| The unit meets the standard |

ISO3046,ISO8528,GB2820, CE |

|

| Emission: |

Standard |

Optional (can be discharged on request) |

| NOx at 5% oxygen content with 100% load |

< 500 mg/Nm³ |

< 50 mg/Nm³ |

| CO/CH4 at 5% oxygen content with 100% load |

≤600 mg/ Nm³ |

≤60 mg/ Nm³ |

| H2S at 5% oxygen content with 100% load |

≤20 mg/ Nm³ |

≤15 mg/ Nm³ |

| Ambient noise | ||

| SPL at a maximum distance of 7 m (standard environment) | ED1200NGB-6/4 / 87 dB (A) & ED1200NGS-6/4 / 75 dB (A) | |

Ased on dry gas emission values at the rear of the catalytic converter.

- Fuel data

| Fuel |

Natural Gas[1] |

| Engine intake pressure |

3.5Kpa~650Kpa(Configured according to supply requirements) |

| Methane volume content |

≥ 85% |

| Low Calorific Value (LHV) |

Hu ≥ 31MJ/Nm³ |

| The heat consumption rate of the unit |

10 MJ/kWh |

| Air consumption per hour is at 50%.

At 75% of the time At 100% of the time |

170 m3 251 m3 332 m3 |

[1] The relevant data in the technical manual will be revised as soon as the natural gas components are required to be provided by the user.

|

Alternator data |

Gas engine data |

||

| Generator brand |

MECC ALTE |

Engine brand |

Huachai |

| Motor model |

ECO40 1S4 |

Engine model |

Deutz |

| Rated voltage (V) |

400 |

Engine type | Inline-6-cylinder-turbocharged |

| Rated power(H class) (KW ) |

320 |

Bore × stroke |

132mm×145mm |

| Rated Capacity (Class H) (KVA) |

400 |

Displacement(L) |

11.9 |

|

Motor Efficiency (%)/(400V) |

94.5 |

Compression ratio |

11 |

| Power factor |

0.8 |

Rated output power |

320kW/1500rpm |

| Connection |

D/Y |

Maximum lubricant consumption(g/kW.h) |

≤0.3 g/kW.hr |

| Rotor insulation rating |

H Class |

Minimum air intake(kg/h) |

1150 |

|

Rated temperature rise |

H Class |

Ignition method | Electronically controlled single-cylinder independent high-energy ignition |

| Excitation method |

Brush-less |

Fuel control mode | Equivalent combustion, closed-loop control |

| Rotate speed(min-1) |

1500 |

Debugging mode |

Debkingmaud |

| Enclosure rating |

IP23 |

||

The alternator complies with GB755, BS5000, VDE0530, NEMAMG1-22, IES34-1, CSA22.2 and AS1359 standards.

If the rated supply voltage changes by ±2%, an automatic voltage regulator (AVR) must be used.

- IG 200 control system

IG200 genset paralleling controller is used for manual/automatic paralleling system of multiple generator sets of the same

capacity or different capacity, as well as suitable for constant power output and mains grid connection of a single generator

set, so as to realize the automatic start-up and shutdown/parallel operation, data measurement, alarm protection and “three

remote” functions of the generator set. The controller adopts a large-screen liquid crystal (LCD) graphic display, which can

display Chinese, English and other languages, which is simple to operate and reliable to operate.

Key Benefits:

→ Support engines, including electronic units – ECUs and mechanical engines. Full control of the engine, alternator and

control technology from a single unit, providing consistent and time-appropriate access to all measurement data;

→ Automatic, manual, and remote start/stop modes of operation;

→ Island application support, mains power failure auto-start (AMF) application support;

→ It has the functions of historical record query, timing clock, automatic power on/off, etc.;

→ With PLC programming function and RS485 communication interface, with Ethernet monitoring mode, to achieve remote

monitoring;

| Description of the performance of the control system | |

| Detection accuracy:0.5% | Power saving mode (backlit LCD) provides longer battery life |

| Power consumption of the whole machine 7W | Monitor single/three-phase voltages, frequencies, load currents, and power factors of generators and main grids; |

| Working conditions: | Monitor engine safety parameters such as lubricating oil pressure, engine temperature and fuel level; |

| Temperature:-25℃~70℃ | Automatic commissioning mode (2 events) to start or stop the genset at a pre-configured time |

| Humidity:20%~90%

IP65 Degree of protection: IP65 (front panel) |

An event log of up to 100 events provides real-time clock (RTC) time logging and engine hours information |

| Modbus RS-485 communication | Counters for parameters such as engine start, operating hours, kWh and kVAh |

| Control start relays, fuel relays, stop relays, and alarm buzzers support charging motor I/O interfaces | Multi-level passwords to avoid unauthorized changes to the profile

CANbus for engine communication, supporting Stage 5/Tier 4 Final standards |

- Standard configuration

| Motor | Dynamo | Cabinet and base | Control cabinets | ||||

| Gas engine Motorized ignition system Air-fuel ratio control Electronic speed control system Electric starting motor | 4sets 4sets 4sets 4sets 4sets | Alternator Class H Insulation AVR Voltage Regulator Power Factor Control | 4sets

|

Steel base Engine stand Stillbass Cabinet (waterproof) Air filtration system | 4sets

4sets 4sets 4sets 4sets |

Main circuit breaker (Delixi) Main Controller(IG200) Communication interfaces Electrical switchgear Lighting, ventilation and cooling control systems | 4sets 4sets 1set 1set |

| Gas supply system | Lubrication system | Standard voltage | Intake/exhaust system | ||||

| Gas manifold Gas leak protection Pressure regulating system | 4sets | Oil filter Engine oil antifreeze | first first first | 400V/220V | Oil filter Exhaust muffler Exhaust bellows, heat shield | 4sets 4sets 4sets | |

| Gas manifold | Services & Documentation | ||||||

| Manual shut-off valves Pressure gauge Gas filters Safety solenoid valve (optional explosion- proof type) | 4sets

4sets 4sets |

Toolkit Installation and operation Manual installation dimension drawing Exterior Dimension Drawing | 1set 1set 1set 1set | Electrical wiring drawings Certificate List of supplies Test report | 1set 1set 1set | ||

- Optional

Engine

|

Dynamo

|

Voltage

|

| Spark plug

Jacket water preheater |

AC synchronous motor: Stamford, Leroy-Somer, MECC,China Motor PMG,Moisture-proof and anti-corrosion treatment, marine motors, PMG, pressure regulators |

Medium Pressure/High Pressure |

| Electrical system | Gas supply system | Crew Auxiliary Facilities |

Remote monitoring ATS switchgear Main power output distribution (multiple power outputs) Controller: parallel and other functions |

Unit Fuel Inlet Pressure Range - Decompression System Gas flow meters, flame arresters, filters Gas pretreatment system The main engine of the gas alarm system |

Flue gas collection muffler (waste heat utilization interface)

Ultra-quiet cabinet accessory |

| Services & Documentation | Exhaust system |

Waste heat system

|

| Service tools

Maintenance and repair parts (air cleaners, oil filters, spark plugs) |

SCR Exhaust Gas Aftertreatment Unit - SCR Protective cover to prevent contact Secondary muffler - noise reduction Exhaust port reversing pipe, tee |

Emergency radiators

Waste heat recovery system |

Paint, size and weight of generator sets – ED1200NGB-6/4 (rainbox)

|

|

Unit Dimensions (L * W * H)mm

|

10000mm×3000mm×4290mm (Minimum transport height: 2591mm) |

Unit weight (dg)

|

18500

|

Exterior spray color

|

(RAL 9016 & RAL 5017 & RAL 9017 ) High-quality polyurethane paint |

Paint, size and weight of generator sets – ED1200NGS-6/4 (silent box)

|

|

Unit Dimensions (L * W * H)mm

|

10000mm×3000mm×4290mm (Minimum transport height: 2591mm) |

Unit weight (dg)

|

20500

|

Exterior spray color

|

(RAL 9016 & RAL 5017 & RAL 9017 ) High-quality polyurethane paint |

Note: The above dimensions and weights are for standard products only and are subject to change, the final data has been drawn.

Reviews

There are no reviews yet.