Description

1. Project overview

Project Name: 4.2MW/600V Drilling Rig Power Supply Project

Project Introduction: 4.2MW/600V gas generator set as the power supply of the project drilling rig;

2. Technical scheme of the project

The gas generator set recommended by our company is connected to the power supply, and the specific configuration is as follows:

a) 2400kW/600V container gas generator set, quantity 1 set;

b) 1800kW/600V container gas generator set, quantity 1 set;

The total power supply of the equipment is 4200kW,

Dimensions:

3. Unit introduction

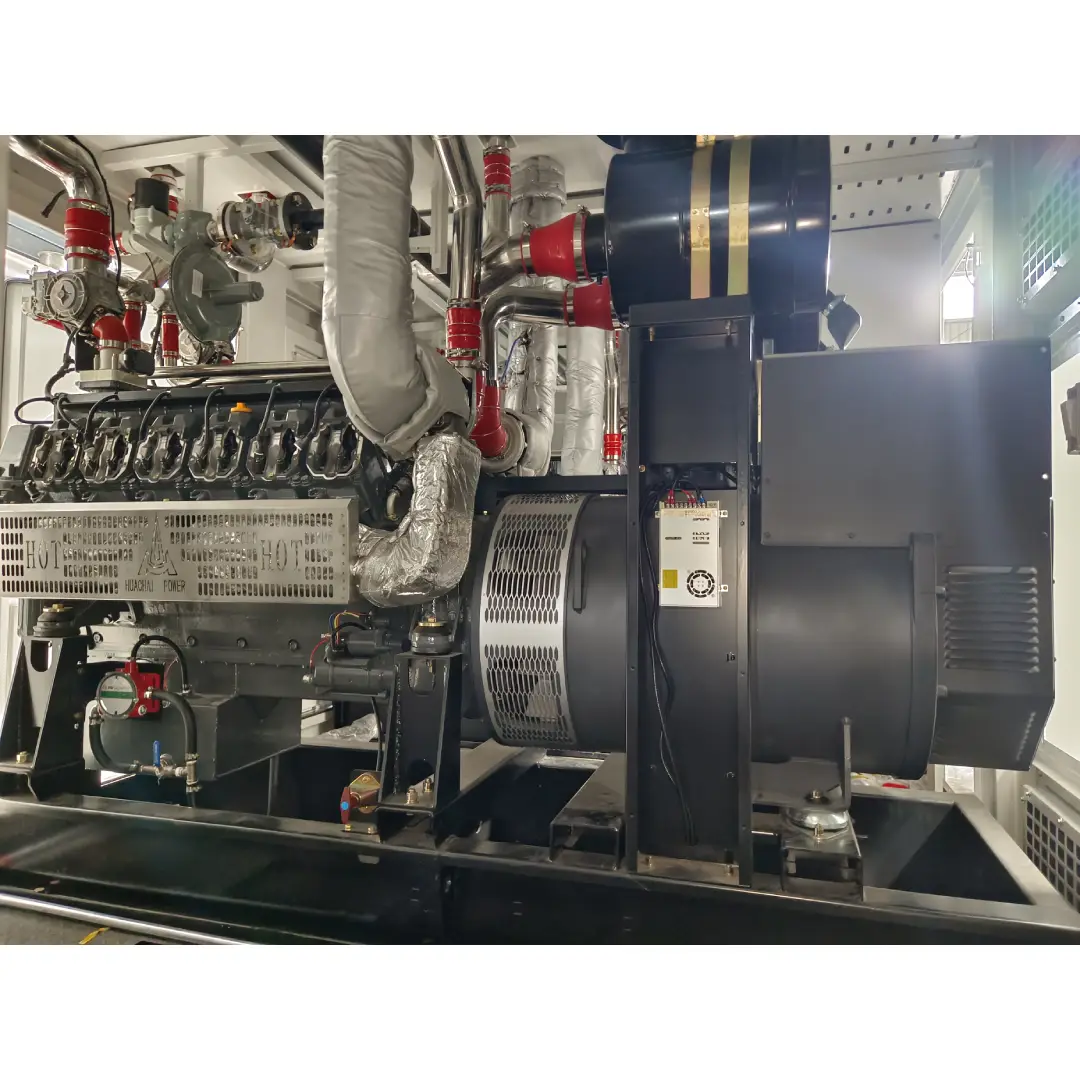

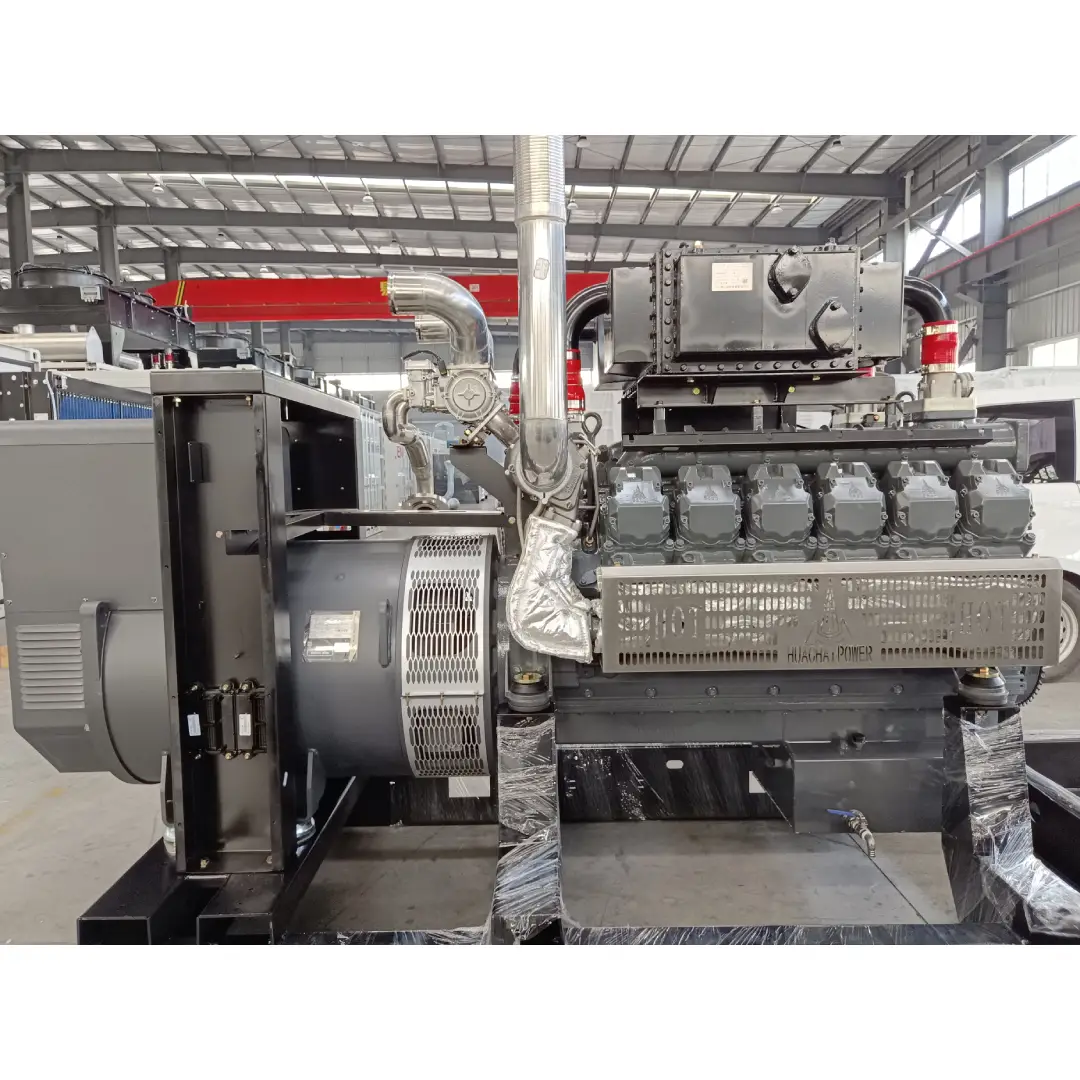

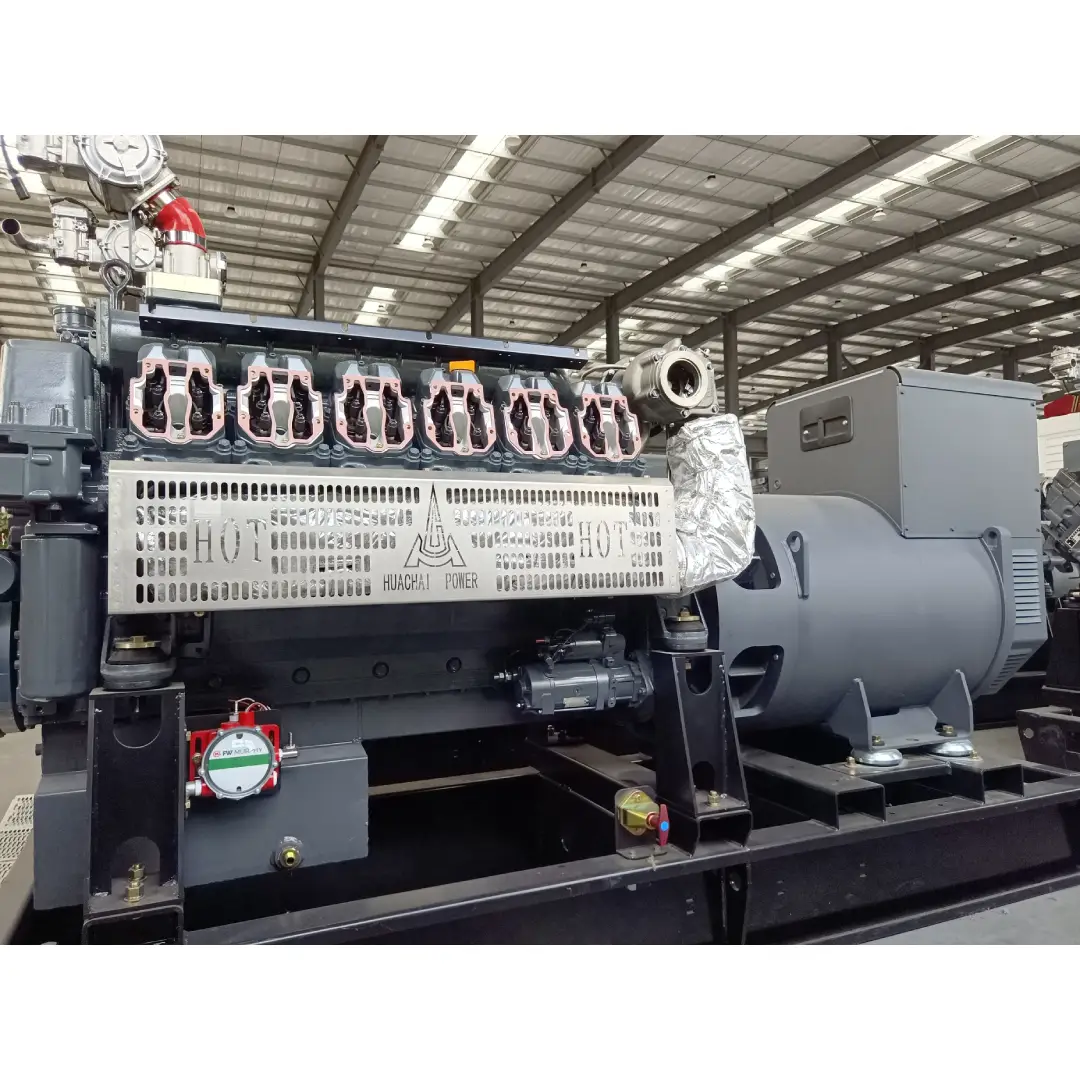

3.1 Skid-mounted box

The gas generator set is composed of a number of modular 600kW gas units, and the skid-mounted box is a customized

container box designed by our company, and the surface of the box is coated with high-grade polyurethane, which is bright

and wear-resistant. The box is divided into a control room, a crew compartment and a radiator compartment, and is

equipped with an air intake noise reduction module.

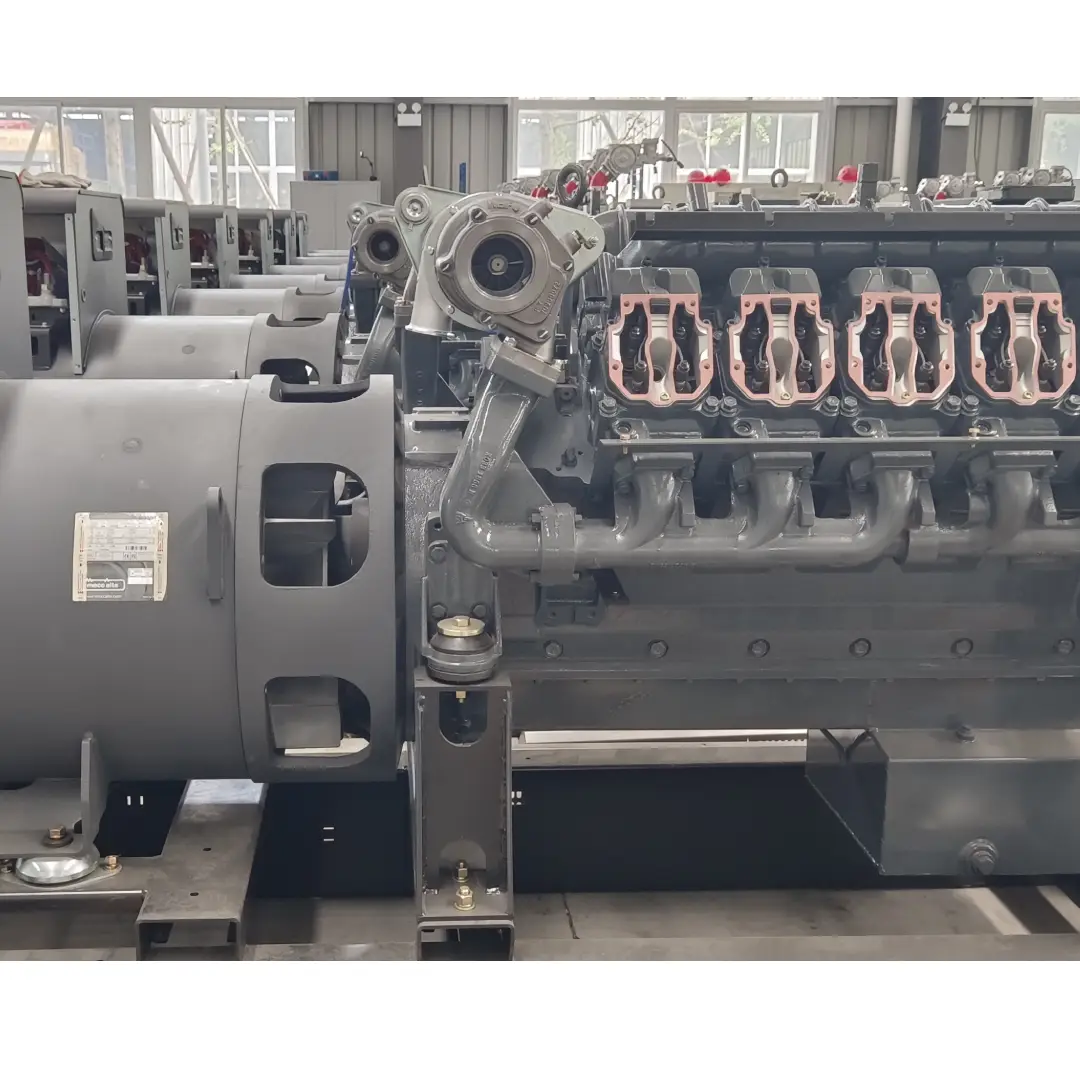

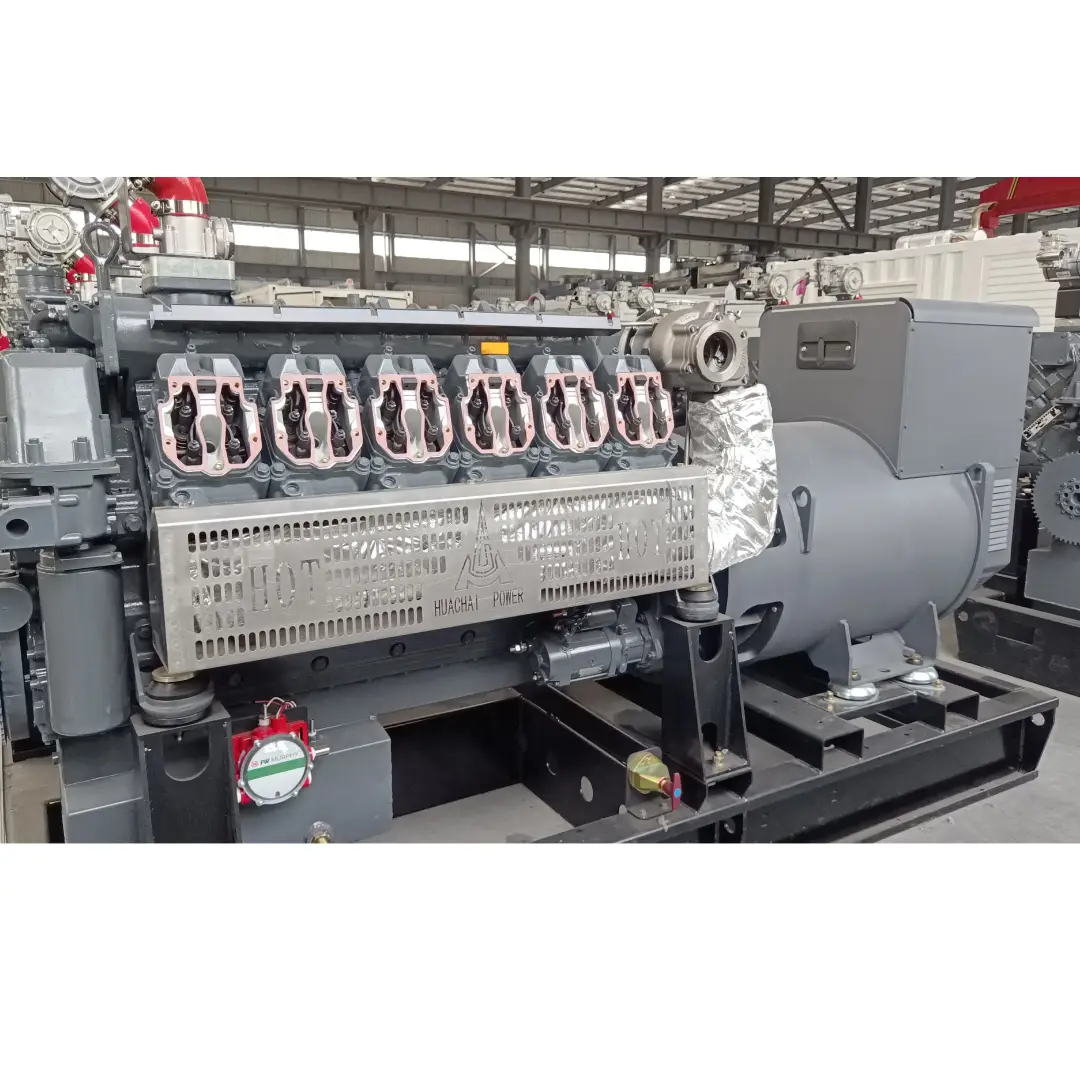

3.2 Natural Gas Engines

The engines are all developed in depth by the Deutz gas engine platform: the software and hardware of the gas control

system are optimized, and the main improvements are made The product can better meet the special requirements of

gas turbines in the field of LNG production: taking into account power response and fuel economy, improving stability

and safety, improving adaptability to high and low temperature environments, improving high humidity environmental

adaptability and fuel compatibility, etc.

The engine adopts imported gas closed-loop lean combustion control system, including: single-cylinder independent ignition

system, electronic speed control system, fuel closed-loop control system, environmental adaptive system and automatic

diagnosis and protection system and other functions to ensure accurate and reliable control of the whole working condition

of the engine, which can well meet the requirements of the engine’s economy, power and emissions. In addition, our company

conducts in-depth optimization and calibration according to the actual use environment, working conditions and fuel

composition of the engine, so that the power response of the gas engine is faster, the economy is better, the stability is stronger,

and the protection function is more complete.

3.3 Generators

The Italian Meaudi series brushless AC synchronous generator is used to customize and strengthen the moving parts, and at

the same time improve the performance of the generator in terms of load impact resistance and anti-interference, so as to ensure

the stability and reliability of the long-term operation of the equipment.

3.4 Unit control system

Using parallel control system, the control system can realize the functions of automatic start, speed, closing, paralleling,

automatic load distribution, transfer, opening, cooling shutdown and other functions, and at the same time, the remote control

system of the engine unit is configured according to the project requirements to realize the remote monitoring and operation

of the generator set operation.

| Item NO. | The name of the project | Specifications/Parameters | |

| 1 | Unit name | 2400kW natural gas generator set | |

| 1.2 | Rated power | 2400kW | |

| 1.3 | Current rating | 2886A | |

| 1.4 | Rated voltage | 600V | |

| 1.5 | Rated frequency | 50Hz Customizable | |

| 1.6 | Startup mode | DC24V electric start | |

| 1.7 | Speed regulation mode | Electronic speed regulation | |

| 1.8 | Fuel control mode | Lean burning | |

| 1.9 | Ignition method | Electronically controlled single-cylinder independent high-energy ignition | |

| 1.10 | Unit operation type | One-key automatic start and stop | |

| 1.11 | Oil consumption rate | ≤0.3g/kWh | |

| 1.12 | Power generation efficiency | ≥36.5% (60% load or more) | |

| 1.13 | Unit dimensions | 12192×3000×4700mm | |

| 1.14 | Unit weight | 27500kg | |

| 1.15 | Noises | 85 dB(A) /7m | |

| 2 | Motor | ||

| 2.1 | Brand | Developed based on Deutz in Germany | |

| 2.3 | Stand-alone exhaust capacity | 23.5 | |

| 2.4 | Air intake type | Turbocharged, forced intercoolant, 4-valve construction | |

| 2.5 | Rated speed | 1500r/min | |

| 2.6 | Rated rotation speed | Forced water cooling | |

| 2.7 | Lubrication method | Pressure, splash lubrication | |

| 2.8 | Oil temperature | ≤108℃ | |

| 3 | Dynamo | ||

| 3.1 | Dynamo | Italian brand | |

| 3.2 | Power factor | ECO40-2L4 | |

| 3.3 | Power generation efficiency | 0.8 (lag) | |

| 3.4 | Generator capacity | 94.5% | |

| 3.5 | Number of phases | 3 | |

| 3.6 | Insulation rating | H | |

| 3.7 | Ingress protection | IP23 | |

| 4 | Crew control system | ||

| 4.1 | Brand | COMAP | |

| 4.2 | Controller functions | One-key start-stop function, data display, recording, protection monitoring and other functions; Remote cell phone monitoring system | |

| 4.3 | Display features | Speed/oil pressure/water temperature/operating hours/current/voltage/frequency/battery voltage/active power, reactive power, load distribution ratio, etc.; | |

| 4.4 | Protection features | Automatic control and alarm functions such as high water temperature, low oil pressure, overspeed, overcurrent, AC and DC voltage, short circuit, etc.; | |

| 5 | Box | Container structure: operating noise 85dBA/7 m | |

Technical parameters of 1800kW natural gas generator set

| Item NO. | The name of the project | Specifications/Parameters |

| 1 | Unit name | 1800kW natural gas generator set |

| 1.2 | Rated power | 1800kW |

| 1.3 | Current rating | 2165A |

| 1.4 | Rated voltage | 600V |

| 1.5 | Rated frequency | 50Hz Customizable |

| 1.6 | Startup mode | DC24V electric start |

| 1.7 | Speed regulation mode | Electronic speed regulation |

| 1.8 | Fuel control mode | Lean burning |

| 1.9 | Ignition method | Electronically controlled single-cylinder independent high-energy ignition |

| 1.10 | Unit operation type | One-key automatic start and stop |

| 1.11 | Oil consumption rate | ≤0.3g/kWh |

| 1.12 | Power generation efficiency | ≥36.5% (60% load or more) |

| 1.13 | Unit dimensions | 12192×3000×4700mm |

| 1.14 | Unit weight | 24000kg |

| 1.15 | Noises | 84 dB(A) /7m |

| 2 | Motor | |

| 2.1 | Brand | Developed based on Deutz in Germany |

| 2.3 | Stand-alone exhaust capacity | 23.5 |

| 2.4 | Air intake type | De Floped, De Barcel, Dendots, Ingerman |

| 2.5 | Rated speed | 1500r/min |

| 2.6 | Rated rotation speed | Forced water cooling |

| 2.7 | Lubrication method | Pressure, splash lubrication |

| 2.8 | Oil temperature | ≤108℃ |

| 3 | Dynamo | |

| 3.1 | Dynamo | Italian brand |

| 3.2 | Power factor | ECO40-2L4 |

| 3.3 | Power generation efficiency | 0.8 (lag) |

| 3.4 | Generator capacity | 94.5% |

| 3.5 | Number of phases | 3 |

| 3.6 | Insulation rating | H |

| 3.7 | Ingress protection | IP23 |

| 4 | Crew control system | |

| 4.1 | Brand | COMAP |

| 4.2 | Controller functions | One-key start-stop function, data display, recording, protection monitoring and other functions; Remote cell phone monitoring system |

| 4.3 | Display features | Speed/oil pressure/water temperature/operating hours/current/voltage/frequency/battery voltage/active power, reactive power, load distribution ratio, etc.; |

| 4.4 | Protection features | Automatic control and alarm functions such as high water temperature, low oil pressure, overspeed, overcurrent, AC and DC voltage, short circuit, etc.; |

| 5 | Box | Container structure: operating noise 85dBA/7 m |

Important note: This is only a demonstration of the plan, if you need a detailed plan, please contact us.

Reviews

There are no reviews yet.