Description

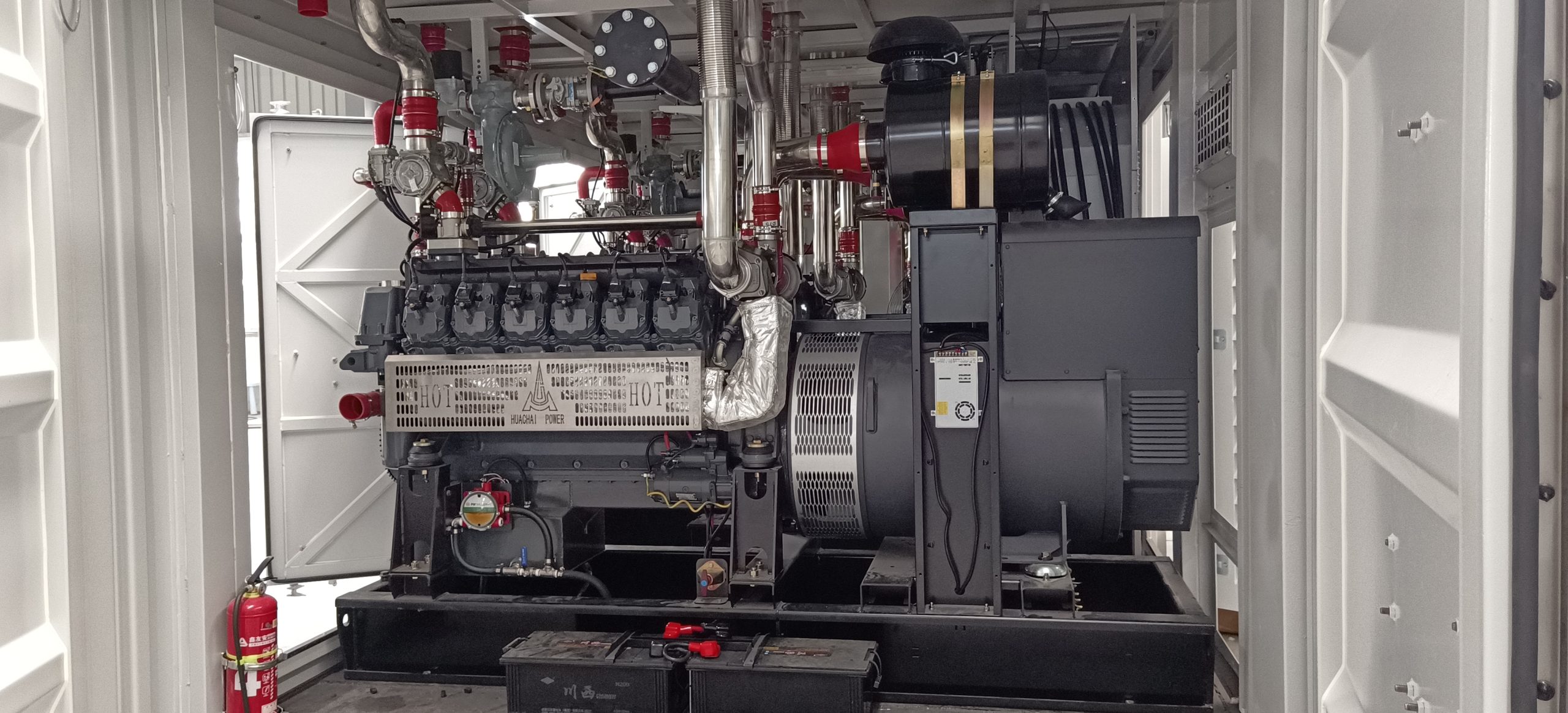

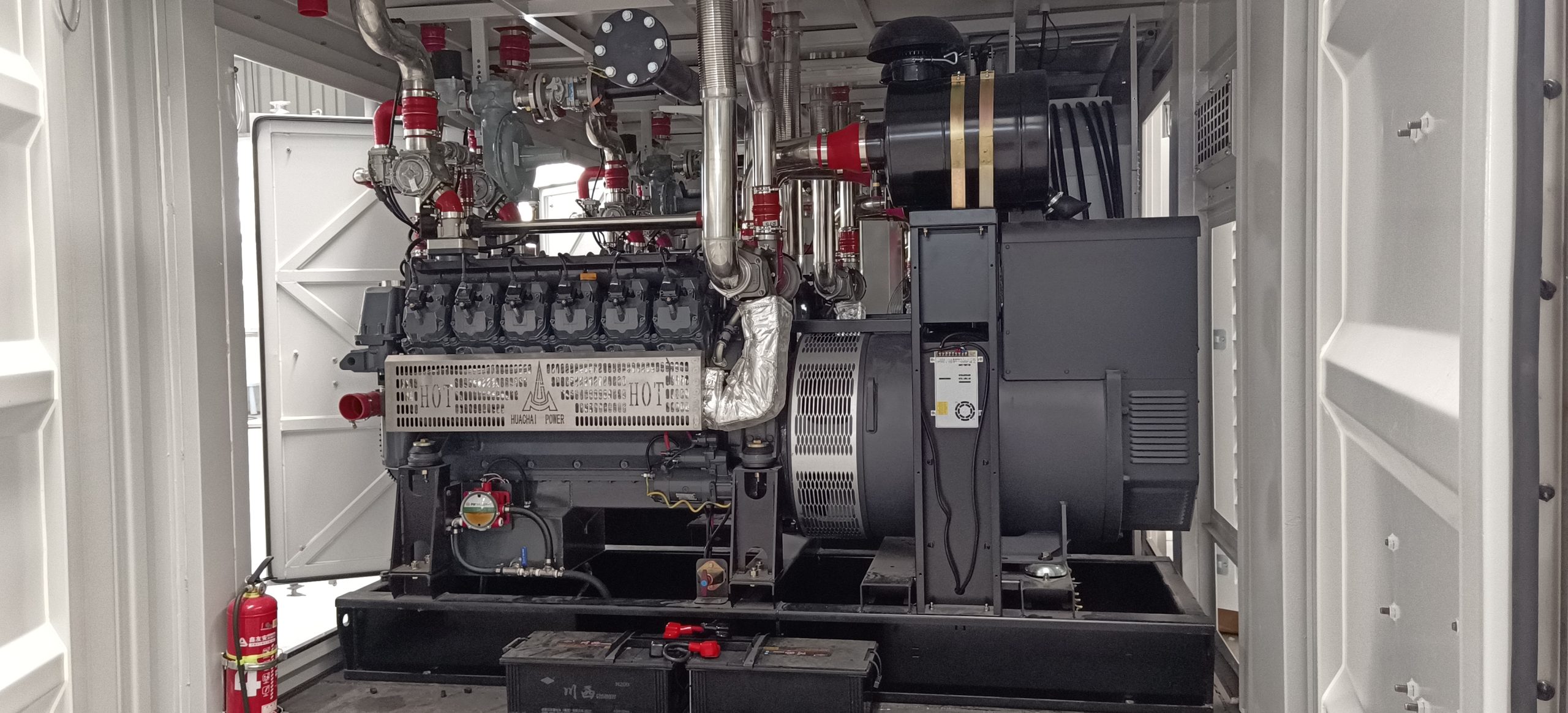

GE ED0600NGD-6_6-HC12V132-S-60Hz-600V Natural Gas Generator Set 600KW

Model #: ED0600NG-6/6 (Engine Model :HC12V132N6)

Main configuration and features: □ Highly efficient gas engine. □ AC synchronous alternator. □ Gas safety valve bank. Gas protection device against leakage is optional. □ Cooling system suitable for ambient temperature up to 50℃. □ Strict shop test for all gensets. □ Industrial silencer with silencing ability of 12-20dB(A). □ Advanced engine control system: ECI control system including: ignition system, speed control system, protection system, air/fuel ratio control system and cylinder temperature system. □ With cooler and Temperature Control System to make sure the unit can work normally at 50℃ environment temperature. □ Independent electrical control cabinet, remote control is available. □ Multi-functional control system with simple operation. □ Data communication interfaces integrated into control system. □ Monitoring battery voltage and charging automatically. |

Generator Data Description

|

Fuel type

|

Natural GAS

|

Equipment type

|

ED0600NG-6/6

|

Equipment configuration

|

Power supply+ Heat Dissipation System + Control cabinet + Steel skid base (ED0600NG-6/6) |

Genset compliance with standard

|

ISO3046,ISO8528, GB2820, CE

|

Continuous output

|

|||

Load

|

50%

|

75%

|

100%

|

Power output KW

|

300

|

450

|

600

|

Fuel consumption KW

|

827

|

1219

|

1579

|

Efficiency in mains parallel mode

|

|||

Continuous output

|

50%

|

75%

|

100%

|

Electrical efficiency %

|

36.2

|

36.8

|

38.0

|

Current (A)/ 600V / F = 0.8

|

360

|

540

|

720

|

Special statement:

This solution is only an example of a specific environment, and does not represent the final demand

technology, providing your specific needs and gas source data, we will tailor it for you.

Main Power Operating Data

|

|

Synchronous alternator

|

Delta, 3P4h

|

Frequency Hz

|

60

|

Power factor

|

0.8

|

Rating (F) KVA prime power KVA

|

750

|

Generator voltage V

|

600

|

Current A

|

720

|

Starter battery 24V, capacity required Ah

|

200×2

|

Starter motor kWel. / VDC

|

7.5 / 24

|

Genset performance data and manufacturing technology

|

|||

Overload run-time at 1.1 times (hour)

|

1

|

Signal interference factor (TIF)

|

≤50

|

Voltage setting range

|

≥±5%

|

Signal harmonious factor (THF)

|

≤2%,as per BS4999

|

Steady-state voltage deviation

|

≤±2%

|

Manufacturing technology ● Special welded base frame, inner vibration isolators and design for whole lifting ● With high-class paint, endurable brightness as well resistance against abrasion and defacing ● Installation manual, operation and maintenance manual wiring program Standards and certificate ● ISO3046,ISO8528,GB2820 ● GB2820BS5000PT99, AS1359 ● ISO9001:2016 Quality system certification ● Alternator compliance withGB755, BS5000, VDE0530, NEMAMG1-22, IED34-1, CSA22.2 and AS1359 standard. |

|

Transient-state voltage deviation

|

-10%~15%

|

||

Voltage recovery time (s)

|

≤2

|

||

Voltage unbalance

|

1%

|

||

Steady-state frequency regulation

|

±1.5%

|

||

Transient -state frequency regulation

|

-15%~10%

|

||

Frequency recovery time (s)

|

≤5

|

||

Steady-state frequency band

|

1.5%

|

||

Recovery time response (s)

|

0.5

|

||

Line Voltage Waveform Sine Distortion Ratio

|

≤ 5%

|

||

Emission data [1]

|

||

Exhaust flow rate (wet)

|

3024 kg/h

|

|

Exhaust flow rate (dry)

|

2380 Nm3/h

|

|

Exhaust temperature

|

500 ℃

|

|

Front side max. allowed exhaust back pressure

|

5kPa

|

|

Genset compliance with standard

|

ISO3046,ISO8528, GB2820,

|

|

Emission:

|

Standard

|

Option (as per requirement)

|

NOx, at 5% residual oxygen&100% load

|

< 2.187 g/kW.h

|

< 0.4 g/kW.h

|

CO, at 5% residual oxygen&100% load

|

< 2.843 g/kW.h

|

< 3.5 g/kW.h

|

NMHC, at 5% residual oxygen&100% load

|

< 0.546 g/kW.h

|

<0.285 g/kW.h

|

Environmental noise

|

||

Sound pressure level at a distance of up to 7 m (standard)

|

90 dB (A) / No protective cover type

|

|

- Based on dry exhaust value at the end of catalyst.

Fuel Data

|

|

Fuel

|

Natural gas [1]

|

Gas intake pressure

|

450kPa-700kPa

|

Methane volume content

|

≥ 90%

|

Low heat value (LHV)

|

Hu ≥ 31.4MJ/Nm3

|

Gas Consumption per hour at 50% load

|

83 m3

|

at 75% load

|

122 m3

|

at 100% load

|

158 m3

|

[1] After the Natural gas components need to be provided by users, the relevant data of the technical manual will be revised. Gas hoses are ECER110 approved. Components in the gas train meet Directive 90/356/EWG. |

|

Service

|

|

Oil level (ambient temperature is higher than minus

5°C/ ambient temperature is lower than minus 5°C)[2]

|

API 15W-40 CF4 /API 10W-30 CF4

|

Lubricating oil capacity min./max.

|

N/A / 60L (Engine)

|

Equipment coolant usage volume min./max.

|

110L / 120 L

|

Coolant type

|

50% softened water and 50% anti-freezing solution (ethylene glycol,

with the concentration of the anti-freezing solution between

40%-68% )

|

Maximum pressure loss in front of air cleaner

|

5 mbar

|

Combustion air temperature minimum /design

|

5 ℃ / 35℃

|

Installation room ventilation (inlet air volume flow )

|

>40000 m³/h

|

●The oil standard refers to factors such as local ambient temperature and air pressure.

AC Generator performance data

|

Gas engine data

|

||

Generator brand

|

Mecc

|

Engine brand

|

DEUTZ

|

Motor type

|

ECO40 VL4C

|

||

Voltage(V)

|

600

|

Engine type

|

V12 cylinders, Exhaust turbocharger with

water-cooled turbine housing

|

Rated (H) KW prime power

|

600

|

Bore x Stroke (mm)

|

132mm×145mm

|

Rated (H) KVA prime power

|

750

|

Displacement (L)

|

24

|

Alternator efficiency (%)

|

95.2

|

Compression ratio

|

12.0

|

Power factor

|

0.8

|

Rated output power

|

630kW/1500rpm

|

Wiring connection

|

3/4

|

Oil consumption max.

|

≤0.3 g/kW.hr

|

Rotor insulation class

|

H class

|

Min Intake flow (kg/h)

|

2880

|

Rated temperature-rise

|

F class

|

Ignition method

|

Electrically controlled single cylinder independent

high-energy ignition Equivalent combustion, closed loop

|

Excitation method

|

Brush-less

|

Fuel control mode

|

Equivalent combustion, closed loop control

|

Rated speed(min-1)

|

1500

|

Speed regulation mode

|

Electrical regulate

|

Housing protection

|

IP23

|

||

Control system

The parallel control cabinet adopts ComAp InteliGen as the main control module. The function of this programmable control system includes engine protection and control, connection between generator and generator or generator and grid, and communication, etc. Main advantages

|

Control System

|

|

Brand

|

ComAp

|

Controller functions

|

One button for start and stop, Data display, Recording, Protection, Monitoring, etc.

|

Display functions

|

Speed, Oil pressure, Water temperature, Hours of operation, Current, Voltage, Frequency, Battery

voltage, Active power, Reactive power, etc.

|

Protection functions

|

Automatic control and alarm functions: High water temperature, Low oil pressure, Over speed,

Over current, AC/ DC voltage level, short circuit, etc.

|

Standard configuration

|

|||

Engine Control:

|

Generator Control:

|

Other controls:

|

|

Lambda closed loop control Ignition system Electronic governor actuator Start up control Speed control load control |

Power control RPM control(synchronous) Load distribution (island mode) Voltage control |

Voltage tracking (synchronous) Voltage control (island mode) Reactive power distribution (island mode) |

Oil filling automatically lntake valve control Fan control |

Early warning monitoring

|

|||

Battery voltage Generator data: U, l, Hz, kW, kVA, kVAr, PF, kWh, kVAh Genset frequency |

Engine Speed Engine running time Intake pressure temperature Oil pressure |

Coolant temperature Measurement of oxygen content in exhaust gas Ignition status inspection |

Coolant temperature

Fuel gas inlet pressure |

Protection functions

|

|||

Engine protection

|

Alternator protection

|

Busbar mains protection

|

System protection

|

Low oil pressure Speed protection over speed/short speed Starting failure Speed signal lost |

Reverse power Overload Overcurrent Overvoltage Under voltage over/under frequency Unbalanced current |

Overvoltage Under voltage Over/under frequency Phase sequence ROCOF alarm |

Alarm Protection Function High coolant temperature Charge fault Emergency Stop |

Scope of Supply

|

|||

Engine

|

Generator

|

Canopy and base

|

Canopy and base

|

Gas engine Ignition system Lambda controller Electronic governor actuator Electrical start motor Battery system |

AC generator H class insulation AVR voltage regulator PF control PMG |

Steel shell base frame Engine bracket Vibration isolators Soundproof canopy (optional) Dust filtration (optional) |

Air circuit breaker Communication interfaces Electrical switch cabinet Auto charging system |

Exhaust system

|

Lubrication system

|

Standard voltage

|

Induction system

|

Exhaust silencer Exhaust bellows |

Oil filter Sensor |

600V

|

Air filter

|

Safety valve

|

Service and documents

|

|

Manual cut-off valve 450~700kPa pressure gauge Gas filter Safety Solenoid valve (anti-explosion type is optional) Pressure regulator Flame arrestor as (option) Natural gas leakage alarm |

Tools package Installation and operation manual Maintenance manual Software manual Parts manual |

Engine operation Gas quality specification Control system manual After service guide Standard package |

Optional configuration

|

||

Engine

|

Generator

|

Lubrication system

|

Coarse air filter Backfire safety control valve Water heater |

Generator Brand: Stamford, Leroy-Somer, MECC Treatments against humidity and corrosion |

Oil consumption measuring gauge Fuel pump Oil heater Daily auxiliary oil tank |

Electrical system

|

Gas supply system

|

Voltage

|

Remote monitoring Grid-connection Remote control Sensor |

Gas flow gauge Gas filtration Pressure reducer Gas pretreatment Alarm system |

415V 440V 460V |

Service and documents

|

Exhaust system

|

Heat exchange system

|

Service tools Maintenance and service parts |

Three-way catalytic converter Guard shield from touch Residential silencer Exhaust gas treatment |

Emergency radiator Electric heater Heat recovery system Thermal storage tank |

Open frame weight dimensions:

Paints, Dimensions and Weights of the Genset—ED0600NG-5/6

|

|

Genset size (length * width * height), mm

|

3800×1870×2250

|

Genset dry weight (kg)

|

5300

|

Spraying Process

|

High quality powder coating (RAL 9016 & RAL 5017 & RAL 9017 )

|

Dimensions are for reference only.

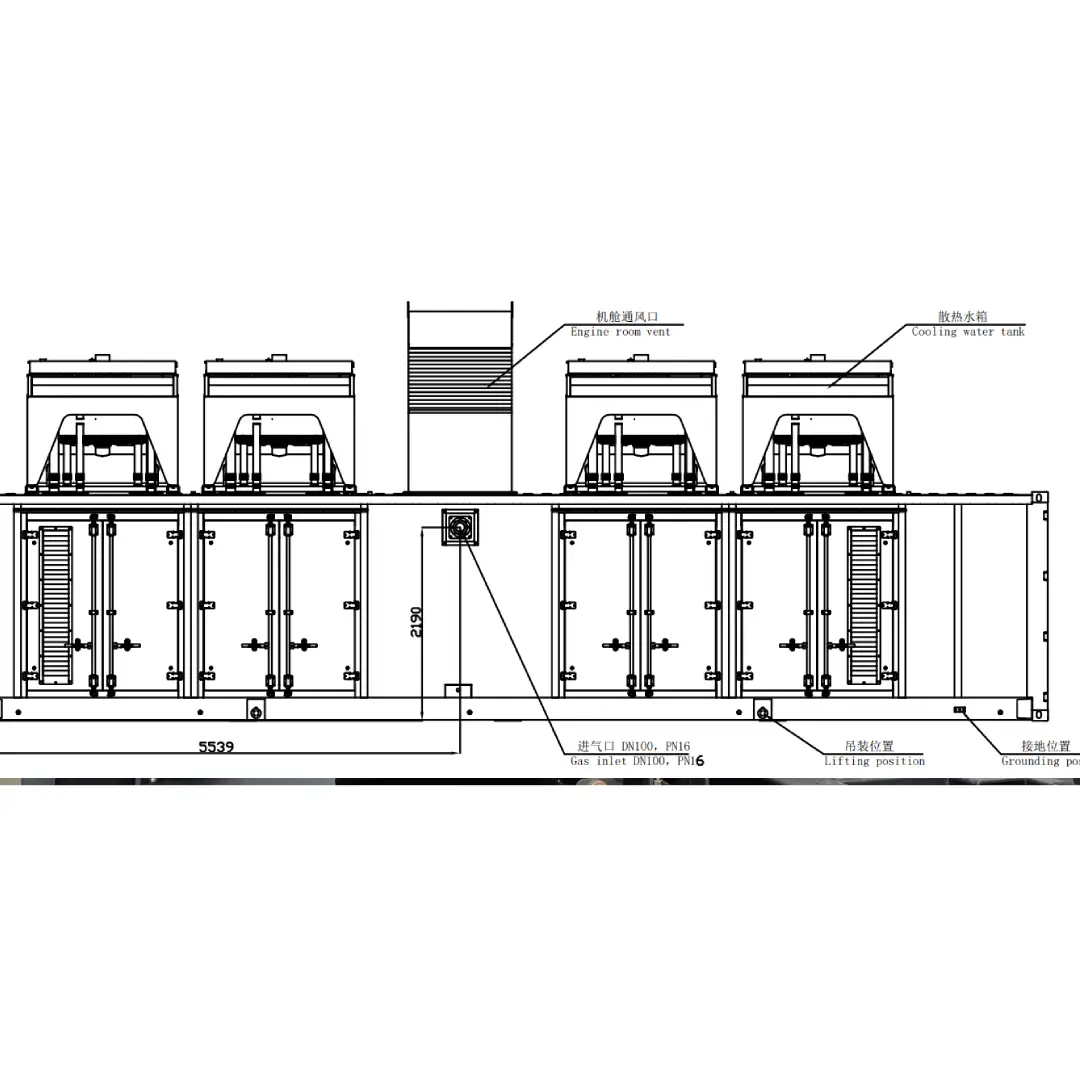

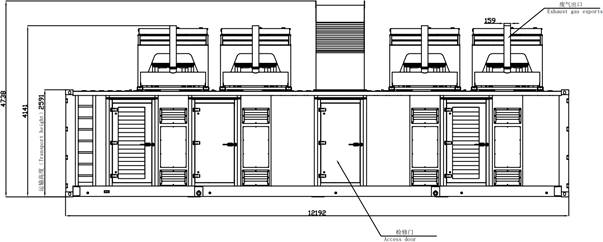

Weight and dimensions of the container canopy structure:

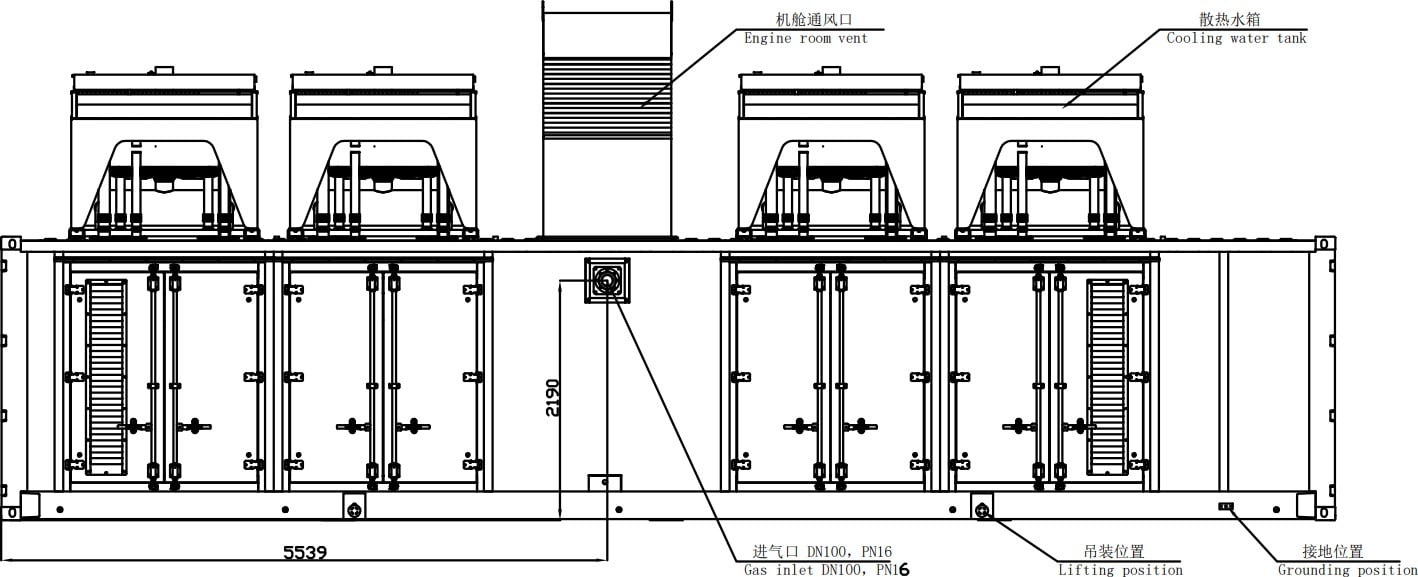

Paints, Dimensions and Weights of the Genset—ED0600NGD 5/6

|

|

Genset size (length * width * height) mm

|

6098×2438×2591(3290 Installing the cooling system)

|

Genset dry weight(Silent Type) kg

|

8300

|

The cooling system weight(Silent Type) kg

|

|

Spraying Process

|

High quality powder coating

|

Data is subject to change without prior notice as new products are always developed. Please contact

local agent with any doubts or for more information.

Reviews

There are no reviews yet.